- Buderusstraße 26, D-35236 Breidenbach

Ground-breaking ceremony for the pilot project 'fire brigade station

After extensive planning, preparations for the construction of the new fire station at the Breidenbach site of Buderus Guss GmbH began in November 2022. The ground-breaking ceremony on 23 February 2023 marked the official start and the base of the Buderus Guss plant fire brigade will be completed by the beginning of 2024 at the latest.

For the plant fire brigade, the investment of millions is an important step within the framework of the safety concept.

Read more in the April 2023 Newsletter

Corporate film 2023

Sustainable braking with Buderus Guss

The new film about Buderus Guss focuses on the strengths and future-oriented activities for sustainable braking.

There is a link to the video on the homepage of the Buderus Guss website.

Read more in the April 2023 Newsletter

Visibility and reach - Buderus Guss relies on transport advertising

Since March 2023, an RMV public transport bus has been on the road with slogans and scenes about Buderus Guss as an ambassador for the company's strengths as an employer and training company.

Stephan Heiderich - Head of Development

Stephan Heiderich took over as Head of Development at Buderus Guss in September 2022.

Read more in the December 2022 Newsletter

Buderus Guss prepares for the future with the iDisc 2nd generation

When the Euro 7 emission standard is adopted, fine dust-reducing brake discs will come into focus.

How Buderus Guss is positioning itself with the new iDisc 2 and the Coating Factory industrialisation project …

Read more in the December 2022 Newsletter

Responsibility for tradition

Buderus Guss GmbH hands over its collection of "Prussian iron art castings" on permanent loan to Sayner Hütte.

The collection of the Buderus Kunstgießerei in Hirzenhain was one of the most important collections of Prussian iron art casting. As the owner of this collection, Buderus Guss has decided to give the more than 1,000 pieces on permanent loan to the Sayner Hütte Foundation in Bendorf.

The Sayner Hütte Foundation will exhibit large parts of them in its new Iron Art Casting Museum, honour their significance as objects of unique casting art and further develop the collection as a whole.

On 13 May 2022, Kathrin Heumann-Kunz (right), representing Buderus Guss, and Jörg Firnges (2nd from right), former head of the Buderus Kunstgießerei, handed over the collection of Prussian iron art castings from Buderus Guss GmbH to the managing director of the Sayner Hütte Foundation, Steffi Zurmühlen (left), and the head of the Iron Art Casting Museum, Barbara Friedhofen (2nd from left).

Read more in the December 2022 Newsletter

Training portfolio expanded

For many years, Buderus Guss has offered its employees the opportunity to prepare for the external examination with the aim of gaining professional qualifications. Up to now, the external training has taken place within the group. Now Buderus Guss has expanded the training portfolio by bundling both the practical and theoretical parts in the training workshop.

Read more in the newsletter May 2022

Optimization projects launched

Burr-free casting of solid brake discs

In order to be able to save a work step in raw casting machining - namely the grinding off of burr residues on the outer diameter of solid brake discs - the feeder connection and the gate geometry were optimised in the casting technology.

Reduction of moulding material costs

Reducing the amount of moulding material on the moulding lines offers potential savings in many respects. According to certain parameters, the quantities of moulding sand per bale were reduced so that, in addition to the savings in process costs, the cycle times could also be effectively shortened in some cases. The aim is to achieve the maximum possible reduction in bale thickness with maximum process reliability.

Read more in the newsletter May 2022

Works council election 2022 at Buderus Guss

At the Buderus Guss sites in Breidenbach and Ludwigshütte, 26 candidates stood for election. The newly elected committee of Buderus Guss GmbH consists of eleven members.

At the constituent meeting on 22 March 2022, Oliver John was re-elected as Chairman of the Works Council and Dietmar Schneider as Deputy Chairman.

Girls' Day at Buderus Guss

"We are glad that after a two-year pandemic, we were finally able to host Girls' Day again locally on April 28," says Henry Hornburg from Buderus Guss Human Resources Development. "We particularly liked the motto 'Adé cliché' because, as a foundry company in times of acute shortages of skilled workers in the MINT sector, we like to make use of the potential that young women bring with them. After all, we have already had many good experiences with female trainees who completed their training with us and then continued their education in master craftsmen's courses or in Studium Plus and are now master craftswomen or engineers with us."

December 2021

Preservation of jobs for severely disabled persons

A crane trolley as a technical innovation serves to preserve jobs for severely disabled persons in mechanical processing. Buderus Guss had this technology, which is unique in Germany, manufactured in order to relieve severely disabled employees. The project was sponsored by the Kassel Integration Office. On-site support was provided by the Integration Service (IFD) of Arbeit und Bildung e.V. Marburg.

Read more in the newsletter December 2021

Investing in productivity

Two examples of how Buderus Guss increases competitiveness and performance balance through investments: The hot blast cupola furnace underwent an optimization of the functional reliability through the replacement of the shell bottom part and the installation of additional temperature sensors. With the investment in the core handling cell, the core production centre is state of the art and optimally equipped for the future.

Read more in the newsletter December 2021

Olaf Ley - Head of Sales and Application Development

In August 2021, Olaf Ley took over as Head of Sales and Application Development at Buderus Guss.

Read more in the newsletter December 2021

Buderus Guss successfully implements holistic perspective for occupational safety.

Through a series of measures, including new communication channels, Buderus Guss has achieved that the safety and health of employees at the sites is a focus topic and that overall the workplaces are even safer.

The campaign "Talking Safety" was launched at the sites with great success. The aim of the campaign was to optimise occupational safety and strengthen the awareness that the safety culture as the foundation for successful companies is a basic attitude that is lived through all hierarchies.

Read more in the August 2021 Newsletter

Corona vaccination campaign at Buderus Guss

The Corona vaccination campaign at Buderus Guss ran from the beginning of June to mid-August 2021 under the motto "Every vaccination counts". Heinz-Dieter Schmidt, the company doctor, and Jürgen Hoffmann from the medical service were able to provide almost 150 employees with the first and second vaccination. The vaccine from BioNTech was used. The campaign on the premises of the Medical Service at the Breidenbach plant was perfectly planned and was very well received by the employees.

Five Buderus Guss employees passed the final examination for "Machine and Plant Operator

(IHK)".

Five employees at the Breidenbach site were able to successfully complete their training as "machine and plant operators (IHK)" through the so-called "external regulation". They were supported by their superiors and the education initiative "ProAbschluss".

They received their skilled worker certificates on 2 July 2021.

Read more in the August 2021 Newsletter

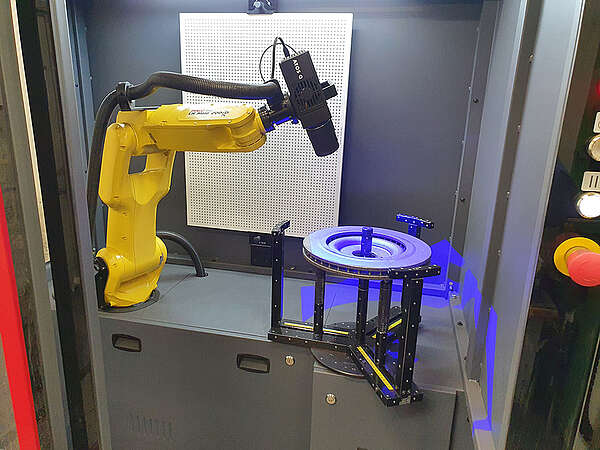

Optical 3D measuring machine Atos Scan Box increases Process quality at Buderus Guss

Since February 2021, an ATOS Scan Box has been available at Buderus Guss in the inspection during production and contributes to increasing the process quality.

The Scan Box is a complete optical 3D measuring machine developed for efficient quality control in the production and manufacturing process. The heart of the system is a 3D scanner. The high resolution and measuring speed of the sensors provide areally distributed 3D coordinates per single measurement. Within 1 to 2 seconds, up to 16 million independent measuring points are acquired. The measurement data is characterized by a high level of detail reproduction.

Read more in the Newsletter April 2021

Christoff Wachendorff, Chairman of the Management Board of Buderus Guss GmbH

Christoff Wachendorff has been Chairman of the Executive Board of Buderus Guss GmbH since February 1, 2021.

The 38-year-old holds a degree in industrial engineering and studied at Darmstadt Technical University.

For him, taking over the management of Buderus Guss is linked to the goal of developing and expanding the company's strengths for the future in the long term through innovative strategies.

Read more in the Newsletter April 2021

Buderus Guss uses interactive communication platform "Active Cockpit”

The Active Cockpit tool is being used with increasing success at Buderus Guss. The platform is an example of how Industry 4.0 changes production and supports continuous improvement.

Read more in the Newsletter December 2020

Successful recruitment of trainees through creative concepts

Despite the corona crisis, seven trainees were welcomed to the Buderus Guss training team. This was achieved through a successful change in recruitment structures.

Read more in the Newsletter December 2020